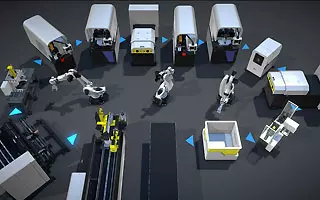

Full auto tube bending machine (CNC)

CNC (Full Auto) Tube bender : PC-Base Control

YLM develops their own CNC software which is based on Windows XP / Windows 7 with the ability to import XYZ information from .dxf / STEP files translating to be YBC data.

YLM software uses 3D simulation software to preview and determine bending interferences. The YLM software is flexible to meet our client's requests to achieve efficient production.

We offer fully automatic tube bending machine CNC-controlled machining of pipes with a diameter from 4mm to 220mm. These models 3,4,5,6,7,8 axial (hybrid models with electrical control in conjunction with the plumbing) and all-electric models in the 10-12 axis...

English

English