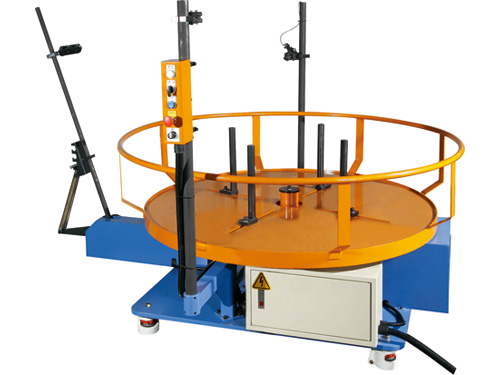

Uncoiler

| Model | CHR-16-3A | CHR-13-3A | CHR-10-3A | CHR-08-3A | CHR-06-3A | |

|---|---|---|---|---|---|---|

| Bending Capacity(mm) | Low carbon | ø 4 ~ ø 16 | ø 4 ~ ø 13 | ø 3 ~ ø 10 | ø 2.5 ~ ø 8 | ø 2.2 ~ ø 6 |

| Mild carbon | ø 4 ~ ø 13 | ø 4 ~ ø 10 | ø 3 ~ ø 7 | ø 2.5 ~ ø 5 | ø 2.2 ~ ø 4 | |

| Max. Number of Bendings | Unlimited | |||||

| Max. Feeding length | Unlimited | |||||

| Machine Processing speed | Feeding (mm/sec) | 1400 | 1700 | 1700 | 1700 | 1700 |

| Rotation (°/sec) | 400 | |||||

| Bending (°/sec) | 400 | 650 | 750 | 800 | 800 | |

| Machine Repeatability | Feeding (mm/sec) | ±0.1 | ||||

| Rotation (°/sec) | ±0.1 | |||||

| Bending (°/sec) | ±0.1 | |||||

| Power (kw) | 33 | 24 | 21 | 13 | 10 | |

| Power source | 3 ø 220V | |||||

| Machine dimensions (mm) | 3690(L) x 1465(W) x 1977(H) | 3590(L) x 1465(W) x 1930(H) | 3500(L) x 1465(W) x 1930(H) | 3500(L) x 1465(W) x 1690(H) | 2750(L) x 1275(W) x 1690(H) | |

| Operating height (mm) | 1415 | |||||

| Overall weight(kg) | 2900 | 2400 | 2300 | 2200 | 1530 | |

| Model | UR130 | UR070 |

|---|---|---|

| Plate dimensions (mm) | ø 1450 | ø 1000 |

| Loading capacity (kg) | 2000 | 500 |

| Mahchine length (mm) | 1780 | 1510 |

| Machine Width (mm) | 1690 | 1455 |

| Machine Height (mm) | 1550 | 1545 |

| Power (kw) | 2 | 1.2 |

| Power source | 3 ø 220V | |

| Overall weight (kg) | 650 | 420 |

Operational

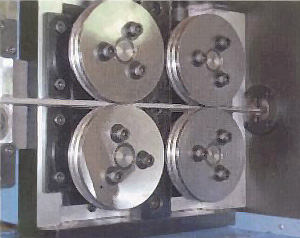

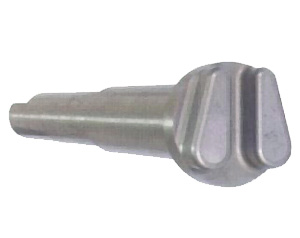

Toooling Design

- Movie

English

English