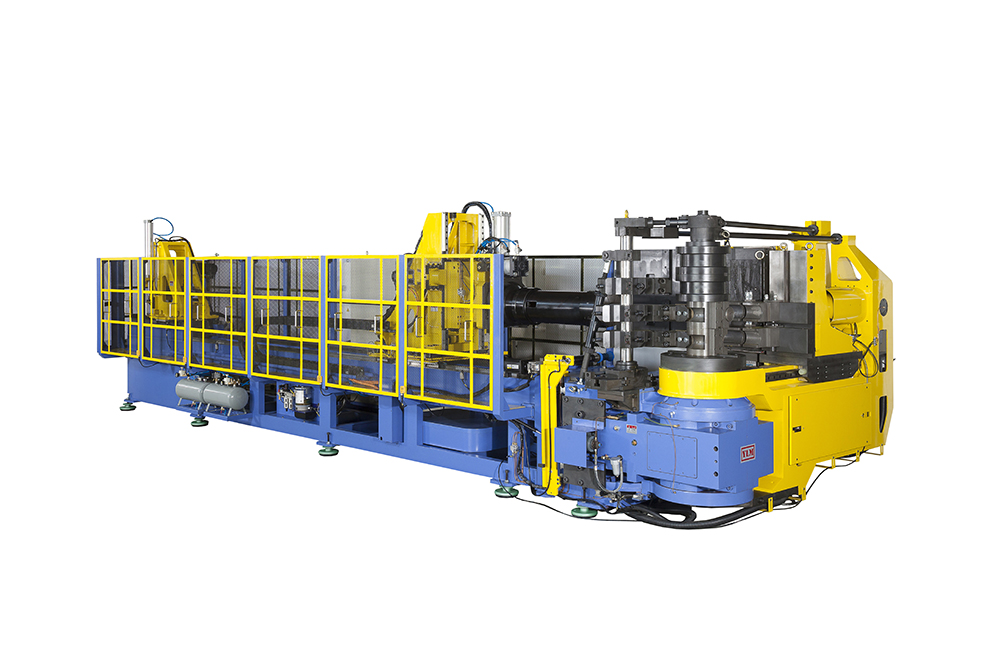

CNC electric tube bending machine

CNC181MS-AE

The CNC tube bender is equipped with a powerful functioning CNC controller. The controller employs a windows operation system in combination with the use of Ying Han self-developed CNC control software. Outstanding features include easy generation of bending parameters, 3D workpiece simulation function and single step operational simulation function, etc. These provide users with safe, easy and humanized control features.

Fully electric CNC pipe bender, All Electric Multi Stack CNC tube Bending machine

Capacity Chart

Specification

| Machine Name | CNC-181MS-AE | |

|---|---|---|

| Max. tube o.d. bending capacity(Mild steel CLR1.5D) (mm) | 180x3.3 | |

| Range of CLR (mm) | 30-370 | |

| Max. bending radius difference (mm) | 150 | |

| Max. bending angle (°) | 190 | |

| Mandrel working distance (mm) | 4500 | |

| Manufacture speed | Max. Tube feeding speed (mm/sec) | 837 |

| MAX. Tube rotation speed (mm/sec) | 506 | |

| Max. Tube bending speed (mm/sec) | 19.53 | |

| Repeatability | Tube feeding Precision (mm) | ± 0.05 |

| Tube rotation Precision (mm) | ± 0.05 | |

| Tube bending Precision (mm) | ± 0.05 | |

| Overall weight (Kgs) | 20850 | |

| Machine length (mm) | 9528 | |

| Machine width (mm) | 3147 | |

| Machine height (mm) | 2364 | |

| Operating height (mm) | 1369 | |

- Movie

- Related Products

CNC electric tube bending machine

CNC151MS-AE

The CNC tube bender is equipped with a powerful functioning CNC controller. The controller employs a windows operation system in combination with the use of Ying Han self-developed CNC control software. Outstanding features include easy generation of bending parameters, 3D workpiece simulation function and single step operational simulation function, etc. These provide users with safe, easy and humanized control features.

English

English