Conventional tube bending machine(CR)

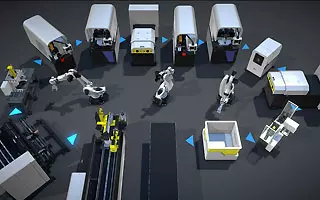

Twin-Head Bender

YLM twin-head tube benders are high production benders capable of making two bends simultaneously. The CR-T38D and CR-T50D are NC controlled with the ability to bend multiple tubes at one-time. The Bend angles can be adjusted to bend at the same angle or two separate angles. The YLM Double Head Benders are the best choice for high production two end bending. YLM Double-Head Benders are suitable for these industries Automotive, Furniture, Hardware, or parts requiring symmetrical bending.

The YLM CR-F38D has the same features as the CR-T38D but is also capable of bending parts with bends on more than one plane. To do this the bend heads are mounted on two rotary tables that can be adjusted to perform multi-plane bends.

Feature

- Proportional pressure controlled hydraulic driven rotation of wiper around the bend die

- Hydraulic clamping of tube between bend die and clamp block

- Hydraulic actuation of pressure die

- Adjustable bending angles from 0 to 180 degrees

- Each side can be set to different degree of bends

- Automatic or manual operation

- Each side speed controlled individually

- Easily accessible multiple Emergency Stops

- Possibility to adjust timing between each motion

- Safety scanners and light curtains (optional)

Material profiles that can be bent on a Double-Head Bender:

- Round Tube or Pipe

- Square or Rectangular Tube

- Angle Iron

- Solid Bar

- Aluminum Profile

- Metal section

With a powerful pipe bender such as the YLM double head compression model mentioned above you can also take on projects that you may have otherwise been reluctant to handle. With minimal instruction you can have your staff producing finished products that would otherwise be impossible. The ability to produce double bends of similar or different angles makes this a powerful yet versatile machine. The complex bends that this machine is capable of handling make this an irreplaceable piece of equipment for your shop. You can also choose from manual or automatic operation depending upon the project and the skill level of the operator. This YLM pipe bender is a workhorse capable of greatly increasing production rates starting on the first day it is setup. With the ability to make bends between 0 and 180 degrees, the options for what you can produce are virtually limitless. When it comes to fabrication businesses, having the ability to make a wide array of products will help your company increase the amount of customers you can work with. This YLM pipe bender will not only increase the amount of production from your shop but it can also provide you with increased quality for your finished products. With the ability to fine tune any of the settings on this machine you have the control needed to make the precision bends that can make the difference between a good job and a great job. The precise control offered by this pipe bender is just one of the many advantages to using this versatile and powerful machine.

English

English